Inspections

We ensure that each stage of the client requirements are fully satisfied before the material and / or equipment leaves the supplier's premises.

Derrick Structure

DERRICK-STRUCTURE

Pre-Fabrication:

- ITP review and Approval

- WPS & PQR review.

- Raw Material.

- Mechanical and Chemical Retest witness

- Incoming material inspection.

During Fabrication:

- Material Traceability verification.

- Fit-up and welding Inspection

- Dimensional inspections.

- WELD & NDT Traceability Report Review.

- Mechanical Completion Inspection of

- AFT Side Horizontal Assembly

- FWD Side Horizontal Assembly

- PORT Side Horizontal Assembly

- STBD Side Horizontal Assembly

- Guide rail Horizontal Assembly

- Finger Board Vertical Assembly

- Water Table Assembly

- Load Test Witness for all Lifting Pad Eye

- Pre Galvanizing & Post Galvanizing Inspection

- Surface preparation & Painting.

- Painting Pull Off Test Witness

- MRB Review.

Offshore Mooring Chain

OFFSHORE MOORING CHAIN

- ITP Review

- Raw Material.

- Mechanical and Chemical Retest witness

- Incoming material inspection.

- Material Traceability Inspection.

- Monitoring of Chain Making

- Bar Cutting , Bar Heating, Bending, Flash Butt Welding, Trimming, Shaping.

- Flash Butt Weld Records Review

- Heat Treatment –Monitoring

- Witness Proof Load Test

- Witness Break Load Test

- Hardness Test - Witness

- Monitoring Splice Link Activities

- Dimension – Witness

- Final NDT- Witness

- Marking & Identification -Witness

- Trial Fit Witness

- MRB Review

High Pressure Pipe

HIGH PRESSURE PIPE

- ITP Review / Approval

- WPS / PQR Review

- Material Traceability Inspection

- Fit -up Inspection

- Weld Visual Inspection

- WELD Traceability Report Review

- NDT Traceability Report Review

- PWHT-Montering

- RT Film and Report Review

- Witness Hardness Test(B,HAZ&W)

- Dimension – Witness

- MCI-Before Hydrotest

- Witness Hydro Test

- Blasting & Painting Inspection

- Final Inspection

- MCI-Beføre Loading.

- MRB Review

Hydraulic Cylinder

HYDRAULIC CYLINDER

- ITP Review and Approval

- WPS & POR Review

- Raw Material Retest Witness.

- Material Traceability Verification.

- Weld Visual Inspection.

- Cylinder Tube Dimensional and visual inspection.

- Chrome Coating Inspection.

- Piston Rod Surface Roughness Inspection

- Honing Inspection.

- Dimensional Inspection.

- Pressure test Witness ( Low Pressure ,High pressure ,Work pressure).

- Friction Test witness

- Leak Test witness

- Oil Cleanliness Witness

- Blasting & Painting Inspection.

- Adhesion Pull Off Test for Painting.

- Mechanical Completion Inspection (MCI) -Before Loading.

- MRB Review.

High Pressure Hoses

HIGH PRESSURE -HOSES

- ITP Review and Approval

- WPS & PQR Review

- Material Traceability Verification.

- Visual Inspection

- Dimensional Inspection.

- Pressure Test witness

- Roughness of ring groove

- Check API Monogram & Label.

- Witness water jet cleaning

- Witness Flushing (TENSIONER HOSE)

- Bore scope Inspection.

- Check Oil Cleanliness Level.

- Safety Clamp Trial Fit.

- Mechanical Completion Dossier -Before Loading.

- Packing & Preservation.

- Preparing of ARP.

- MRB Review

Bulk Tank System

BULK TANK SYSTEM

- ITP Review and Approval.

- WPS and PQR Review.

- Material Traceability Verification.

- Fit-up Inspection.

- Visual Inspection.

- Witness Dimensional Inspection.

- Radiography Film Interpretation & Report review.

- Pressure Test Witness.

- Surface Preparation & Painting.

- Mechanical Completion Dossier.

- Leak Test-CANVAS

- Trail Fit & Factory Acceptance Test (FAT).

- Packing & Preservation

- Preparing ARP

- MRB Review.

Choke & Kill Manifolds

CHOKE & KILL MANIFOLDS

- ITP Review

- Material Traceability Verification

- Visual Inspection.

- Dimensional Witness

- Bolt Torque Inspection

- Pressure Test ( Upstream and Down Stream)

- Surface Preparation & Painting.

- Mechanical Completion Dossier

- Functional tests of Electrical instrumentation by Pressurizing the Choke and Kill Manifold –Verified by the Electrical Control System (CCP)

- Functional tests of Hydraulic instrumentation by Pressurizing the Choke and Kill Manifold –Verified by the Hydraulic Gauges in the Local Control Panel (LCP)

- Remote Operated Choke Valves (LCP & CCP)

- Remote Operated Gate Valves (LCP & CCP)

- Factory Acceptance Test (FAT).

- Preparing ARP.

- MRB Review.

Pressure Vessel & Heat Exchangers

PRESSURE VESSEL & HEAT EXCHANGERS

- ITP Review and Approval .

- WPS and PQR Review .

- Material Traceability Verification.

- Materials retest witness (Mechanical & Chemical Test).

- Fit-up & Welding Inspection.

- Visual Inspection.

- Witness Dimensional Inspection.

- Radiography Film Interpretation & Report review.

- Pneumatic/RF pad test.

- Vacuum Test.

- Hydro Test.

- PMI Test.

- Pressure Test Witness .

- Surface Preparation & Painting.

- Mechanical Completion Dossier.

- Packing & Preservation

- Preparing ARP.

- MRB Review.

Seamless Pipe

SEAMLESS PIPE

- ITP Review and Approval .

- Product Specification review.

- Material Retest Witness.(Mechanical & Chemical).

- Dimensional inspection.

- Thickness Measurement .

- Visual Inspection.

- Colour Coding .

- Witness Ultrasonic Test(UT).

Dual Hoisting Tower

DUAL HOISTING TOWER

Pre-Fabrication:

- ITP review.

- WPS & PQR review.

- Welder qualification witness.

- Raw Material.

- Mechanical and Chemical Retest.

- Incoming material inspection.

During Fabrication:

- Material Traceability verification.

- Fit-up and welding.

- Weld Traceabilty Report Review.

- Dimensional inspections.

- NDT Traceabilty Report Review.

- Mechanical Completion Inspection.

- Horizontal & Vertical Assemblies.

- Guide Rail Horizontal Assembly .

- Bolt Torque Inspections.

- Load Test Witnesses.

- Surface preparation & Painting.

- Painting Pull Off Test Witness .

- Factory Acceptance Test (FAT).

- Preservation.

- MRB Review.

Crown Block Cluster & Turnover Sheaves

CROWN BLOCK CLUSTER & TURNOVER SHEAVES

- ITP Review and approval .

- WPS & PQR Review .

- Material Traceability Verification.

- Fit-up Inspection.

- Visual Inspection.

- Dimensional Inspection.

- Foot Print Inspection.

- Weld Traceabilty Report Review.

- NDT Traceabilty Report Review .

- Monitoring of sheave assembly .

- Inspection of Groove and Sheaves .

- Surface Preparation & Painting.

- Mechanical Completion Dossier.

- Witness of Weighing .

- Trial Fit Test and Factory Acceptance Test (FAT).

- Preservation.

- MRB Review.

Travelling Block

TRAVELLING BLOCK

- ITP Review and approval

- WPS & PQR Review

- Material Traceability Verification

- Fit-up Inspection.

- Visual Inspection.

- Dimensional Inspection.

- Foot Print Inspection .

- Weld Traceabilty Report Review.

- NDT Traceabilty Report Review .

- Monitoring of sheave assembly .

- Inspection of Groove and Sheaves .

- Surface Preparation & Painting.

- Mechanical Completion Dossier.

- Witness of Weighing .

- Trial Fit Test and Factory Acceptance Test (FAT).

- Preservation .

- MRB Review.

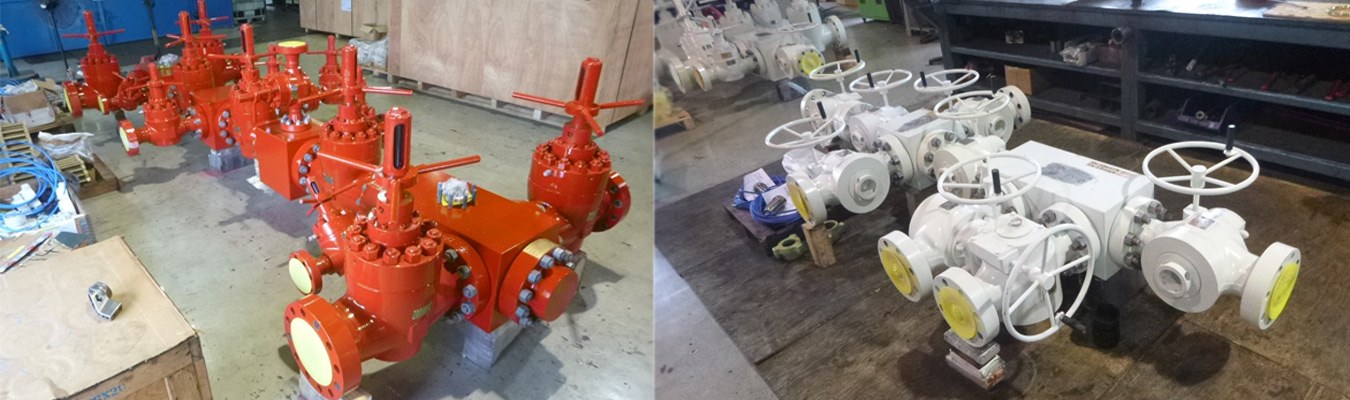

Valves

VALVES

- Material Inspection

- Welding Inspection

- Material Traceability Verification

- NDT Report Review

- PMI Test Witness

- Visual and Dimensional Inspection

- Flange Face Finishing Witness

- Leak Test Witness

- Pneumatic Test Witness

- Hydro static Test Witness

- Low Pressure Air Test

- Hydrostatic Testing

- Post Hydrostatic Testing

- Final Inspection

- Name Plate visual inspection

- Painting and Coating

- Valve Spare Parts, Loose Items and Accessories control

- MRB Review

Mud Gas Seperator & Liquid Seal

MUD GAS SEPERATOR & LIQUID SEAL

- ITP Review and Approval.

- WPS and PQR Review .

- Material Traceability Verification.

- Fit-up Inspection.

- Visual Inspection.

- Witness Dimensional Inspection.

- Radiography Film Interpretation & Report review.

- Pressure Test Witness .

- Surface Preparation & Painting.

- Mechanical Completion Dossier.

- Trail Fit & Factory Acceptance Test (FAT).

- Packing & Preservation.

- Preparing ARP.

- MRB Review.

Bop Skid, X-Mas Tree Skid

BOP SKID, X-MAS TREE SKID

- ITP Review and Approval.

- WPS and PQR Review.

- Product Specification review.

- Raw Material Inspections.

- Material Traceability, Verification.

- Fit-up & Welding Inspection.

- Visual Inspection.

- Dimensional Inspection.

- Weld Traceabilty Report Review.

- NDT Traceabilty Report Review .

- Surface Preparation & Painting.

- Pressure Test (Hydraulic) Witness.

- Mechanical Completion Dossier.

- Trial Fit and Factory Acceptance Test (FAT).

- Packing & Preservation .

- MRB Review.

Above Deck Guid and Overhead Crane

ABOVE DECK GUID and OVERHEAD CRANE

- ITP Review and Approval.

- WPS and PQR Review.

- Product Specification review.

- Raw Material Inspections.

- Material Traceability Verification.

- Fit-up & Welding Inspection.

- Visual Inspection.

- Dimensional Inspection.

- Weld Traceabilty Report Review.

- NDT Traceabilty Report Review .

- Surface Preparation & Painting.

- Pressure Test (Hydraulic) Witness.

- Mechanical Completion Dossier.

- Trial Fit and Factory Acceptance Test (FAT).

- Packing & Preservation.

- MRB Review.

Hydraulic Piping

HYDRAULIC PIPING

- ITP Review and Approval

- Material Traceability Verification

- Visual Inspection

- Dimensional Inspection

- Bending Inspection

- Flaring inspection

- Thickness Measurement

- Hydrostatic Leak Test

- Packing & Preservation

- Mechanical Completion Dossier

- MRB Review

NDT Inspections

NDT Inspections

- Visual Inspection

- Magnetic Particle Test

- Ultrasonic Testing(Conventional & Phased Array )

- Dye Penetrant Test